In the production sector, every second matters. Costly downtimes can result from inefficiencies, equipment malfunctions, and delays. Manufacturers must respond quickly to shifts in production, problems with the supply chain, and equipment performance in order to remain competitive. Manufacturing operations are being revolutionized by real-time event architecture, which makes it possible to respond quickly to important events via multi-channel routing, increasing productivity and adaptability. In the production sector, every second matters. Costly downtimes can result from inefficiencies, equipment malfunctions, and delays. Manufacturers must respond quickly to shifts in production, problems with the supply chain, and equipment performance in order to remain competitive. Manufacturing operations are being revolutionized by real-time event architecture, which makes it possible to respond quickly to important events via multi-channel routing, increasing productivity and adaptability.

What is Business Event Architecture?

A system that records, interprets, and routes real-time events such as machine warnings, supply chain interruptions, or quality control notifications is known as business event architecture in the manufacturing industry. Manufacturers may streamline their processes and cut downtime by forwarding these events to the right channels, like emails for comprehensive reports, webhooks for integrating other platforms, SMS for urgent notifications, and APIs for automated system replies.

Real-Time Routing: Transforming Manufacturing Operations

Here’s how real-time event routing is being used in manufacturing to improve outcomes:

- Preventing Equipment Downtime:

- Scenario: Real-time event routing is integrated with predictive maintenance system of a major automobile manufacturer. When sensors identify unusual vibrations in a vital machine, the event is processed right away and sent to an API, which sets up a maintenance schedule, alerts the production manager via email, and sends an SMS alert to the maintenance team.

- Outcome: By preventing unplanned equipment failures, cutting maintenance expenses, and guaranteeing production continuity, this proactive strategy saves the organization millions of dollars in lost productivity every year.

2. Streamlining Quality Control:

- Scenario: Real-time event routing is used in food processing facilities to keep an eye on the quality of the products being produced. When a problem is found, the event sets off an alarm that stops production, notifies the quality control system via a webhook, and notifies the plant manager by voice alert.

- Outcome: Early defect detection helps the business cut costs, enhance customer happiness and brand reputation, and maintain industry standards while improving product quality and compliance.

3. Optimizing Supply Chain Management:

- Scenario: Real-time event routing is used by a producer of consumer electronics to track supply chain interruptions and inventory levels. The system initiates a sequence of events upon detection of low stock levels: an email alerts procurement to the possible delay, an API call makes a refill order, and an SMS is issued to the logistics team.

- Outcome: This flawless coordination makes sure that production lines are always stocked, which lowers bottlenecks and speeds up delivery, making the supply chain more robust and effective.

Components of Real-Time Event Architecture for Manufacturing:

- Event Sources: Key sources of events in a manufacturing setup include supply chain management data, maintenance alerts, quality control systems, and sensors on production lines.

- Event Processing Engine: In order to decide what to do next, this essential component filters, enriches, and prioritizes raw data from sensors and other sources. For high-performance processing, tools like Azure Event Hub, MQTT brokers, and Apache Kafka are frequently utilized.

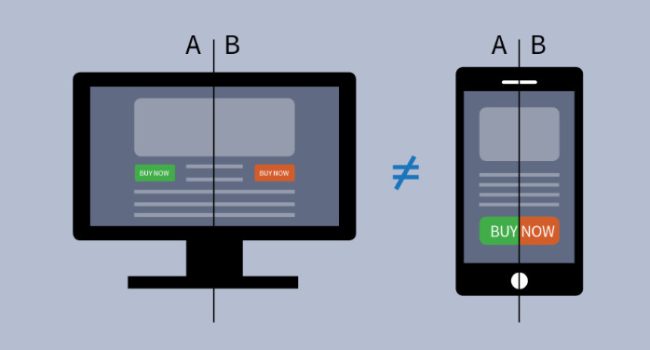

- Event Router: In charge of allocating processed events to the appropriate channels in accordance with predefined guidelines. The router chooses which events may be automated, which can wait, and which require human interaction.

- Communication Channels:

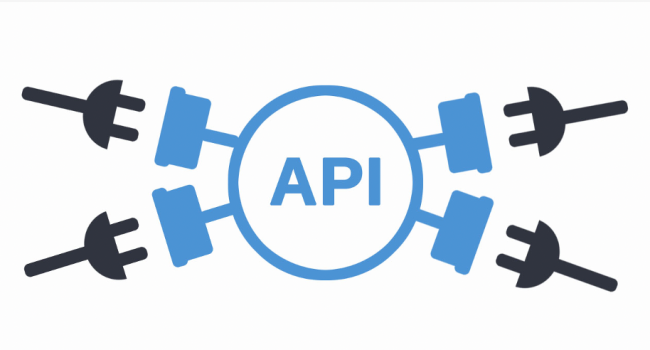

- APIs: Direct communication between automated systems should be made easier to enable quick reactions such as stopping equipment or changing production parameters.

- Webhooks: Used for smooth interaction with other platforms, including third-party analytics tools or supply chain management systems.

- SMS/Voice Alerts: essential for quick communications with plant managers or maintenance crews.

- Email: gives comprehensive reports and notifications for compliance documentation assessment.

Key Benefits of Real-Time Event Routing in Manufacturing

- Minimized Downtime:

- Production lines remain operational thanks to proactive maintenance and real-time notifications, which minimize unplanned stoppages.

- Enhanced Quality Control:

- Quick fixes for quality problems guarantee high standards and cut down on waste and recalls.

- Supply Chain Resilience:

- Manufacturers can react quickly to interruptions and maintain stable operations by using real-time information into inventory and logistics.

- Operational Efficiency:

- Routine task and alert automation simplifies operations and frees up human resources to concentrate on important decision-making.

XR Studios: Your Partner in Manufacturing Optimization

We at XR Studios are aware of the particular difficulties faced by manufacturers. With the help of our custom event architecture solutions, you may improve efficiency, cut costs, and change operations. We give the knowledge and experience you need to stay ahead, from integrating IoT devices to putting up reliable event routing systems.